The nineteenth China International Optoelectronic Exposition (CIOE China Light Expo) was held at the Shenzhen Convention and Exhibition Center on September - 6 - 9. The exhibition site, Dalian Kam shadow Optical Technology Co Ltd (abbreviation: Kam shadow) with high precision and speed, randomly placed China optical instrument, curvature profiler advantages, attracted many visitors to the site look.

With the rapid development of the optical industry, the lens detection needs of enterprises is increasingly strong, there are increasingly high requirements, the widespread use of spherometer, interferometer, profilometer, three coordinates, topography and other testing equipment can not meet the needs of the industrial production of detection. The AncientO-SHF-CM series optical curvature instrument developed by ourselves has met the requirements of industrial 4 on-line batch inspection, and can guide the processing in production. The test results can meet the requirements of the lenses. The device features: non contact measurement, the accuracy of curvature of 1 per thousand; speed up to 5S/, to provide automatic interface; detection can range from 10mm to several meters; simple operation, key detection.

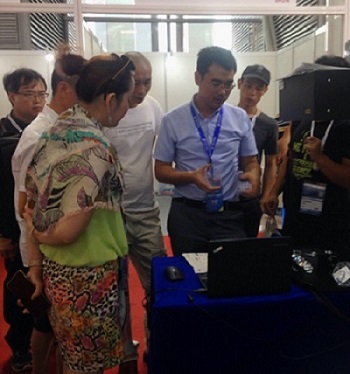

Field inspection lens

In the optical inspection, the biggest advantage of the company is to detect large-size lenses. At the exhibition, the image display, exposure testing machine, glass lens surface instrument, the scene attracted many exhibitors and visitors. AncientO-SHF-GM series optical surface instrument, through non-contact testing method, accurately calculates millions of points of specular surface in 8S, and gives micron surface data and optical characteristics. Equipment features: 10mm 1500mm size can be detected lenses, a variety of surface measurement; 8S within the completion of testing, surface accuracy of 100nm; placing requirements low, suitable for online testing and unknown lens automatic surface analysis.

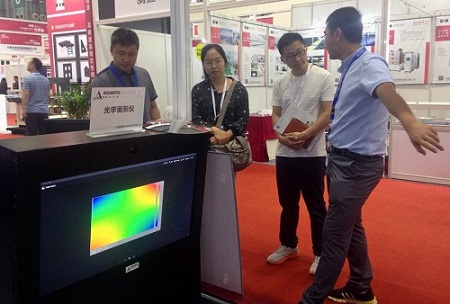

Exhibition live demonstration

In addition, the glasses face shape instrument has also been visited by the attention of many enterprises, and solved some of the glasses enterprises are facing the problem of detection of glasses. AncientO SHF - GD series of glasses profiler of Glasses Global degree, the degree of astigmatism and astigmatism axis of the non-contact detection equipment, using self-developed ATOIAS-D-V1.1 image acquisition system and image processing system ATOIMP-D-V1.1 the fastest in 10S lenses 10000 points are calculated, the accuracy of up to 0.1 degrees; the device is provided with a display diopter image, visual lens, precision 0.2mm PD detection, simple operation, can be a key measure.

In the optical detection industry, with independent property rights in Dalian shadow optical image processing algorithm and coding ability, will have developed a novel optical testing device of high speed and high precision, meet the testing requirements of high precision lens enterprises.