Product features;

■ Multi point non-contact measurement with high accuracy;

Non contact detection, to avoid damage to the workpiece surface.

■ Wide range of detection, high dimensional limit;

Curvity R range: > 100mm

■ Suitable for on-line inspection;

The open communication interface can be used to realize on-line detection with automatic equipment.■ The result can guide the processing;

According to the distribution of the surface quality of the lens, the processing instructions are given.

■ Good usability;

One time setting parameter can be detected by one key, and no standard lenses are needed for comparison, and non-contact testing of various curved lenses can be directly carried out.

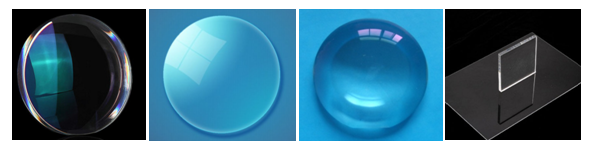

Applications;mainly used in lenses, reflective continuous surfaces, glass and other surface curvity radius, surface detection. The general purpose equipment mainly detects lens products with large area (6-160mm).

■Optical lens inspection;

The various plane, concave, convex, non spherical lens surface curvity fitting analysis and high precision, especially for micro lens curvity detection precision is very high, up to the radius of curvature of 0.1-0.5% precision, and can be fitted out front, to evaluate the lens surface error.

Various types of mirrors and curved mirrors are used to measure the surface type error distribution

■Surface detection;

The system can detect the surface errors of any curved mirror surface, and the axial accuracy is higher than 1nm. Used to test and evaluate surface defects and deformation, and to guide surface restoration.

|

SHF-GMB Series Optical Curvity / Surface Instrument |

||

|

|

High Sperm Type SHF-GMB |

|

|

Serial Name |

SHF-GMB1 |

|

|

Function |

CurvIty Radius Detection |

● |

|

Surface 3D Distribution |

● |

|

|

Auxiliary Machining Function |

● |

|

|

One Key Measuring Function |

● |

|

|

Two-way Adjustment Platform |

● |

|

|

Testing |

Plane |

● |

|

Sphere |

● |

|

|

Aspheric Surface |

□ |

|

|

Hyperboloid |

□ |

|

|

Paraboloid |

□ |

|

|

Free-form Surface |

□ |

|

|

Research Module |

□ |

|

|

Testing |

Measuring Radius Of Curvature,mm |

R>100 |

|

Lens Size,mm |

6-160 |

|

|

Corresponding Plane Size,mm |

10-100 |

|

|

Reflectivity |

≥1% |

|

|

Lens Material |

Unlimited |

|

|

Curvity |

Curvity Accuracy |

0.01‰ |

|

Repeatability Accuracy |

0.002‰ |

|

|

Surface Shape |

PV,nm |

100 |

|

RMS,nm |

20 |

|

|

Image |

Image Acquisition System |

ATIAS-pro |

|

Maximum Collection Pixels |

130w |

|

|

Minimum Acquisition Time |

5s |

|

|

Image Processing System |

ATIMP pro-V1.1 |

|

|

Fastest Processing Time |

3s |

|

|

Data |

Specification Judgment |

□ |

|

Yield Statistics |

□ |

|

|

Real Time Statistics And Display Of Good Yield |

□ |

|

|

Automatic Data Storage |

□ |

|

|

On-line Inspection |

Automatic Access System |

□ |

|

Data Interface |

□ |

|

|

Environmental Science |

Temperature |

10℃-40℃ |

|

Humidity |

10%-80% |

|

|

● To Configure □ Optional |

||